| NO. | ITEM | TEST METHODS | TEST CONDITION | UNIT | Typical value | |

| GX6505 | ||||||

| Physical Propertids | ||||||

| 1 | Density | GB/T1033 | 23ºC | -- | 1.01 | |

| ISO1183 | ||||||

| 2 | Molding shrinkage | GB/T 15585 | ‐ | % | 1.1 | |

| 3 | Shore hardness | GB/T2411 | ‐ | D | 79 | |

| ISO2039 | ||||||

| 4 | Melting point | GB/T 4608 | ‐ | ºC | 195 | |

| ISO3146 | ||||||

| Mechanical Propertie | ||||||

| 5 | Tensile strength | GB/T 1040 | 50mm/min | 50mm/min | ≥45 | |

| ISO527 | ||||||

| 6 | Flexural strength | GB 9341 | 2mm/min | Mpa | ≥40 | |

| ISO178 | ||||||

| 7 | Flexural Module | GB /T9341 | 2mm/min | Mpa | 1100 | |

| ISO178 | ||||||

| 8 | Horizontal burning | UL94-2016 | Level | -- | HB | |

| Remark | ||||||

My company is high-tech enterprise in shandong, China, which mainly produces long carbon chain nylon.

The main products include nylon 610, nylon 612, nylon 1010, nylon 1012, nylon 1212,

transparent nylon and high temperature nylon, exported to Korea, the United States, Germany, Japan,

Turkey and other countries, and with many foreign customers to establish close cooperation.

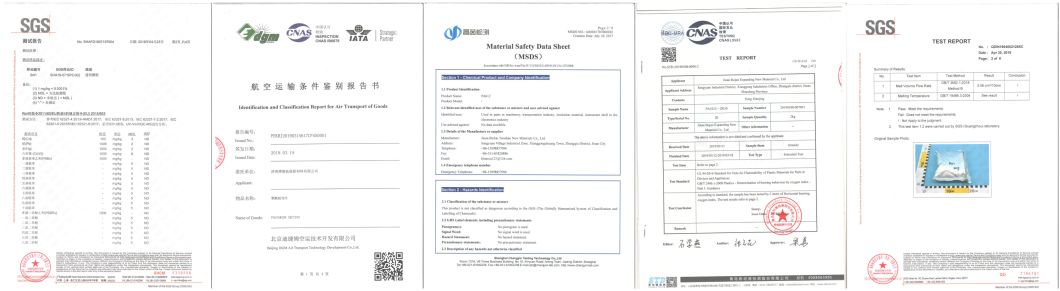

Our ompany has the domestic advanced product inspection equipment, and passed the ISO9001 international quality management system certification, ISO14001 international environmental management system certification, products also passed the REACH, SGS,ROHS, FDA, MSDS and other related certification and testing.

My company's products have good comprehensive performance, a wide range of USES, can replace metal in the mechanical, chemical, instrumentation, automotive and other industries.And the product in the melt spinning, with higher strength, so it can be made into knitwear or blended into wear-resistant clothing materials.

My company's products have good comprehensive performance, a wide range of USES, can replace metal in the mechanical, chemical, instrumentation, automotive and other industries.And the product in the melt spinning, with higher strength, so it can be made into knitwear or blended into wear-resistant clothing materials.

What are the matters needing attention when processing nylon?

1. Use of raw materials

Had better not more than three times, lest cause product discoloration or mechanical physical properties of sharp decline, should be controlled in the dosage below 25%, too much will cause the fluctuation of the process conditions, and then raw materials and new materials must be dry.

2. Safety tips

Nylon type resin boot should first open the nozzle temperature, and then in the feeding cylinder heating, when the nozzle is blocked, do not face the nozzle hole, in case the melt in the cylinder due to pressure accumulation and sudden release, dangerous.